Friday January 24, 2014

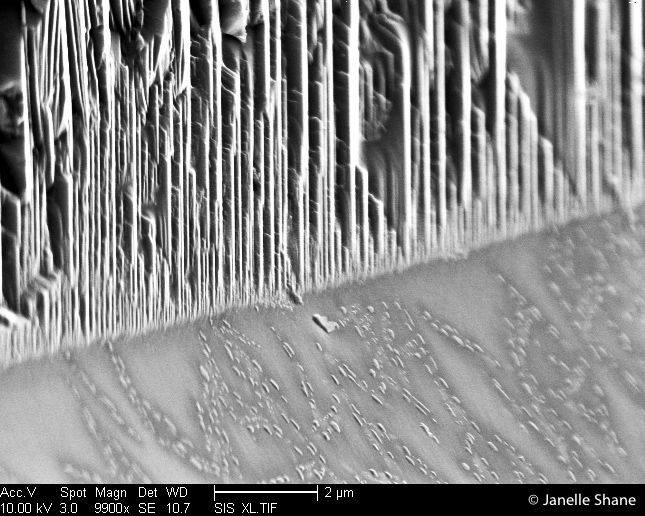

Microscopic fracture patterns appear clifflike on the edge of one of my samples. This entire view is less than 10 micrometers high, meaning that it covers about a tenth the thickness of a typical human hair. We usually don’t get patterns like these, because we use a special wafer dicing saw that uses a sharp blade to get a clean edge. But my notes on that particular sample say “expertly diced, i.e. dropped on the floor” so now we know where the interesting fracture pattern came from. "Floor dicing" does happen, especially when the samples get tiny and the grad student’s tweezer hand gets shaky. My labmates and I have learned that when working with a valuable sample, it’s best to limit multitasking, and to quit after the first signs of fatigue, or disaster will likely follow. On this particular test sample, the broken edge was no problem - I’d envisioned dicing the sample into rectangles, but jagged polygons would also work.